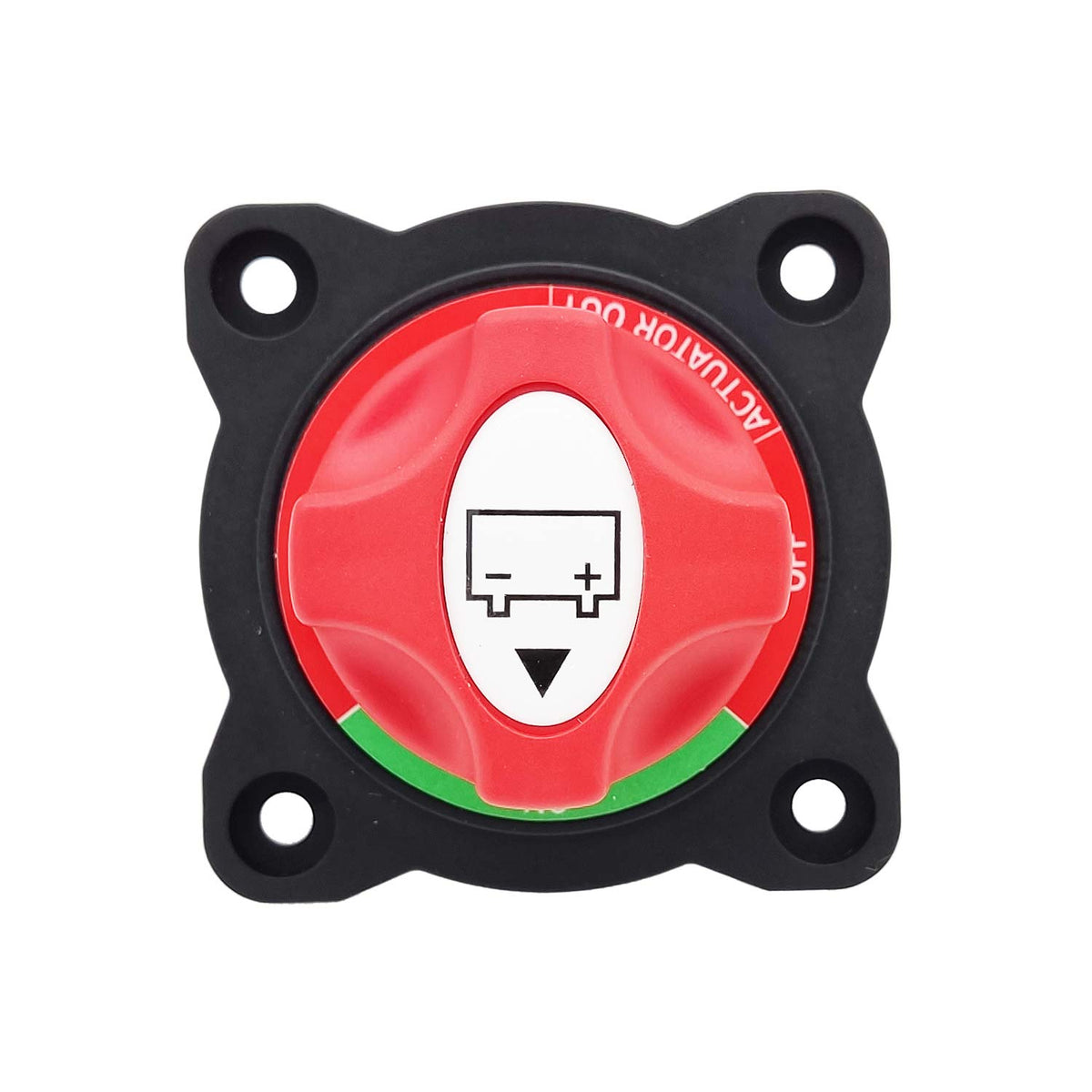

Battery Disconnect Switch for Boat Marine Caravan Truck Car IP54 50V 275A (Max 1250A 5Sec.) 3 Positions (On-Off-Actuator Out)

Battery Switch On-Off-Actuator out 300A-1000A (30sn) IP68

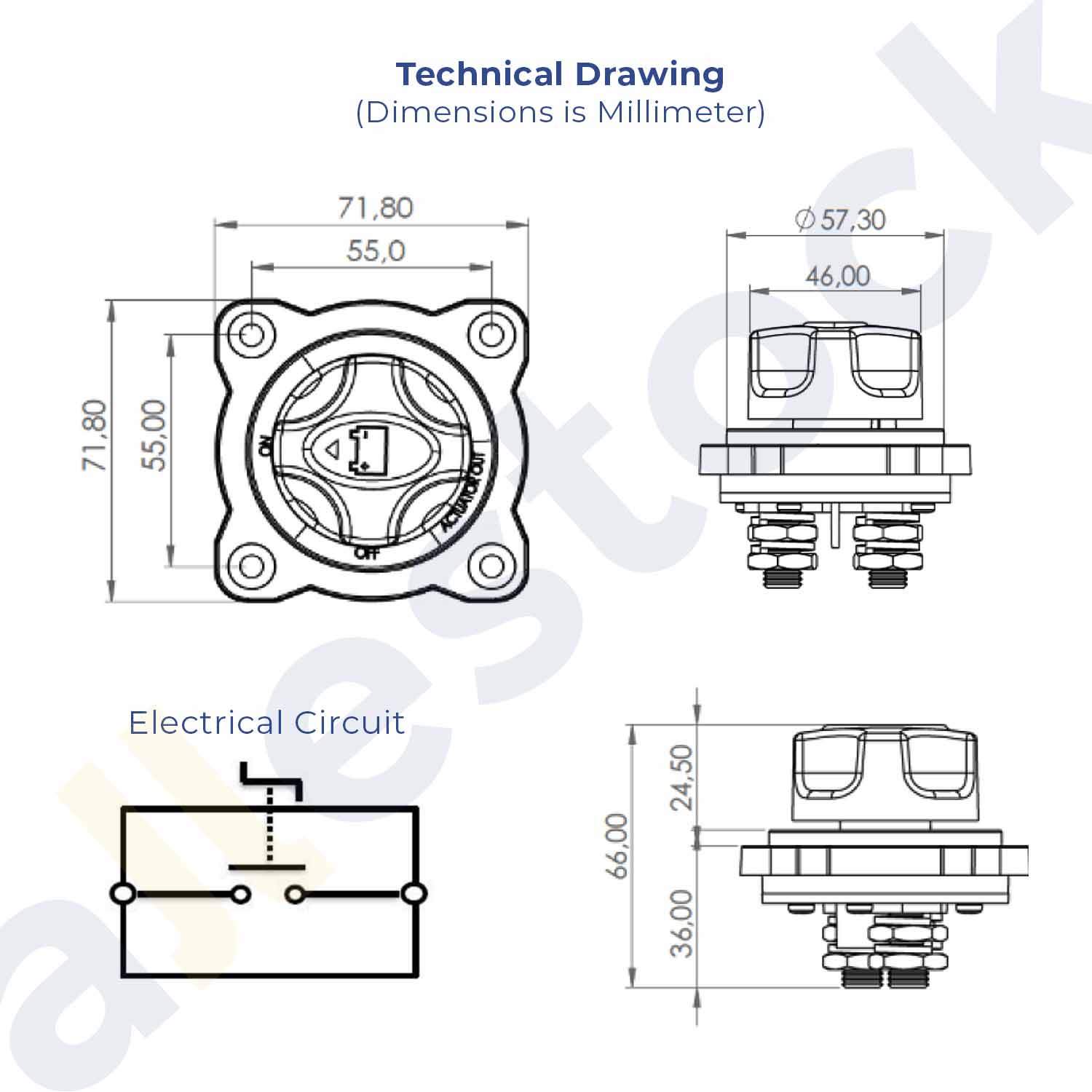

Product Technical Features:

- Operating Temperature: -40 ˚C to +85 ˚C

- Working Voltage: 12-50 V

- Working Current: 300 A

- Maximum Current Capacity: 1000A (30sec)

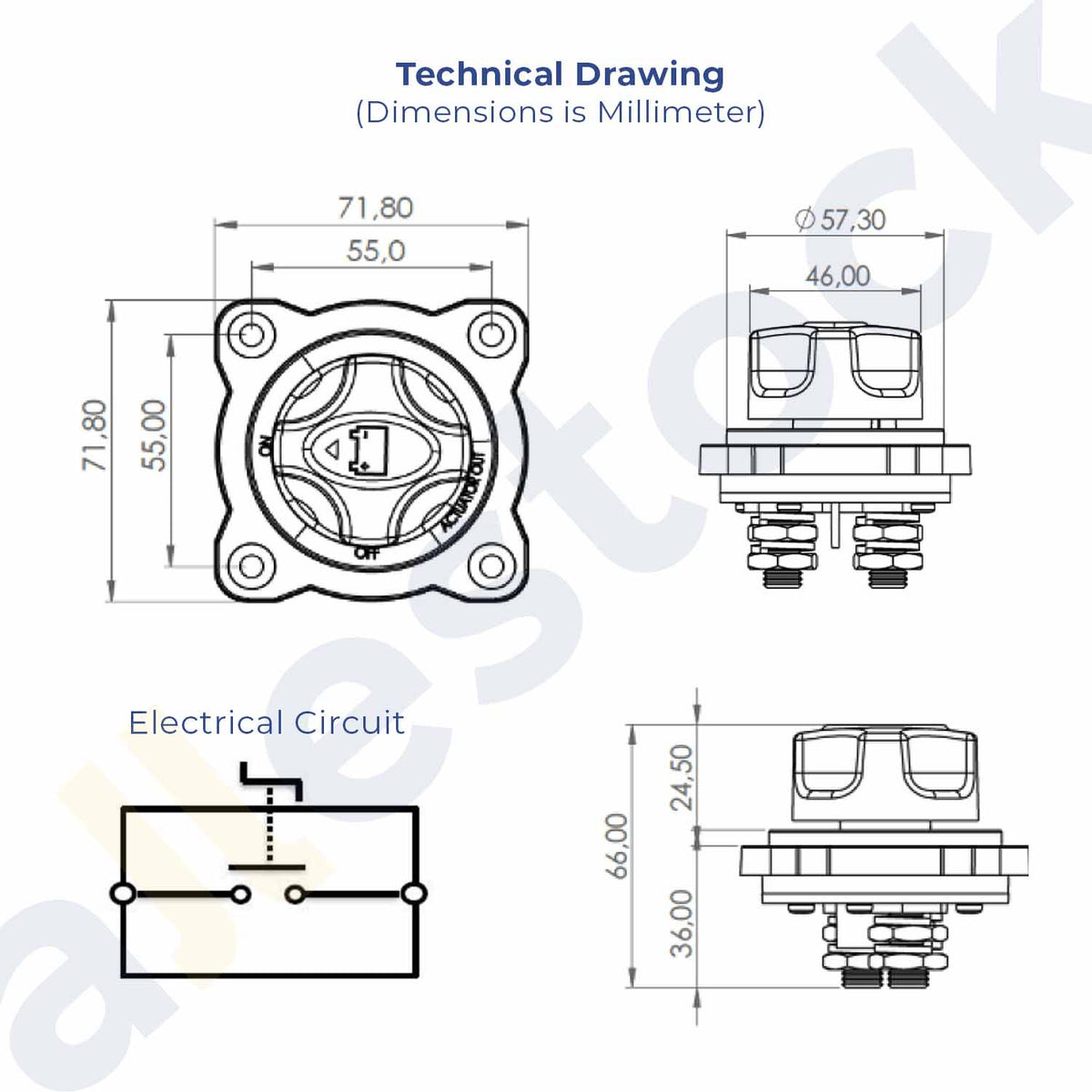

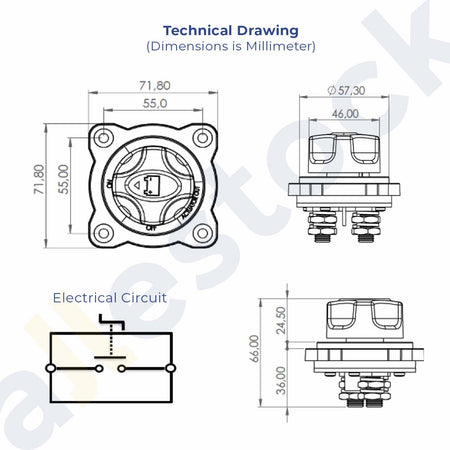

- Connector: 2 x M10 Copper Connectors

- Body Material: PBT GF 30%

- Top Cover Material: PBT GF 30%

- Contact Material: Copper

- Screw Material: Copper

- Nut Type: M10 Brass Nut

- Environmental Resistance: Resistant to UV Rays

- Ingress Protection: IP54

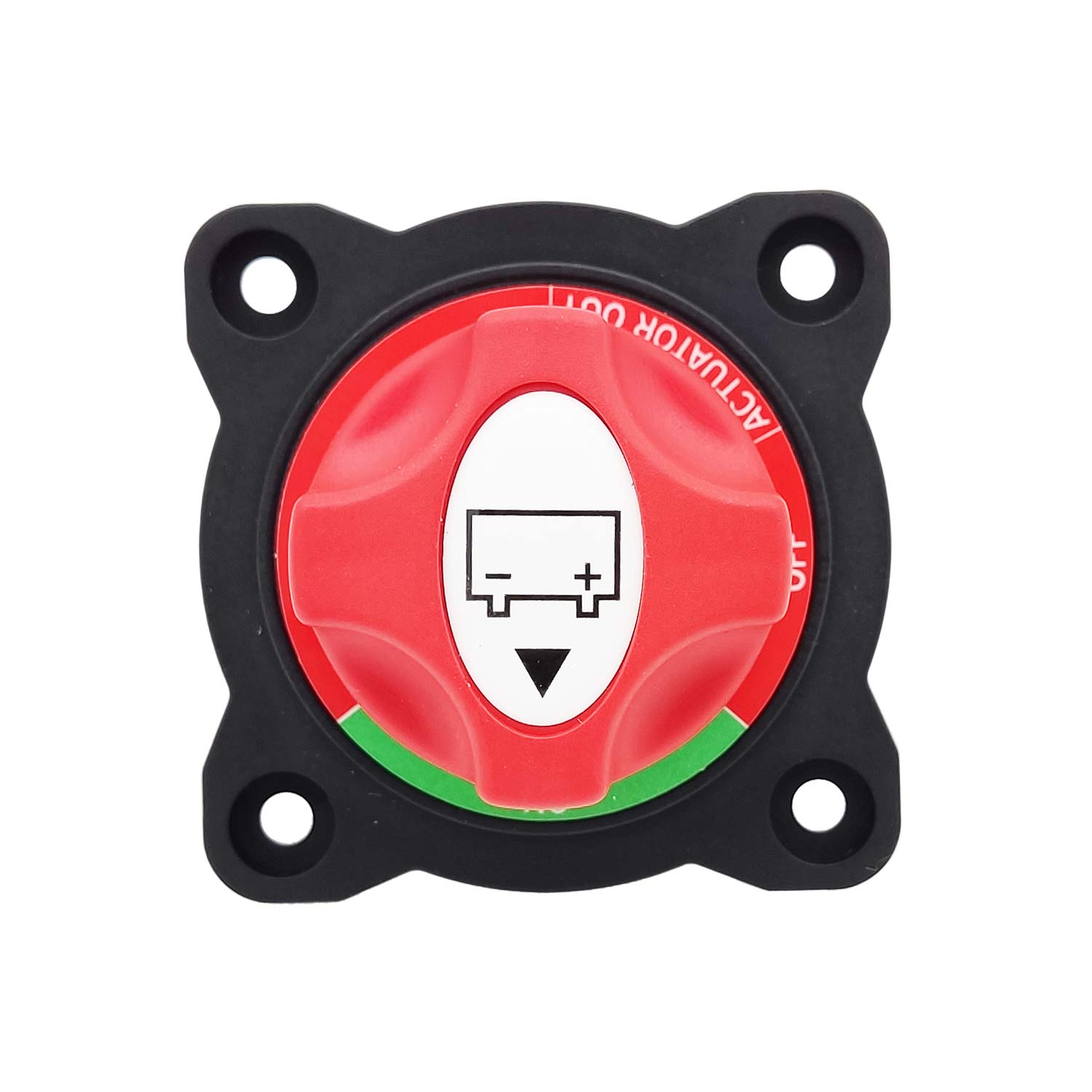

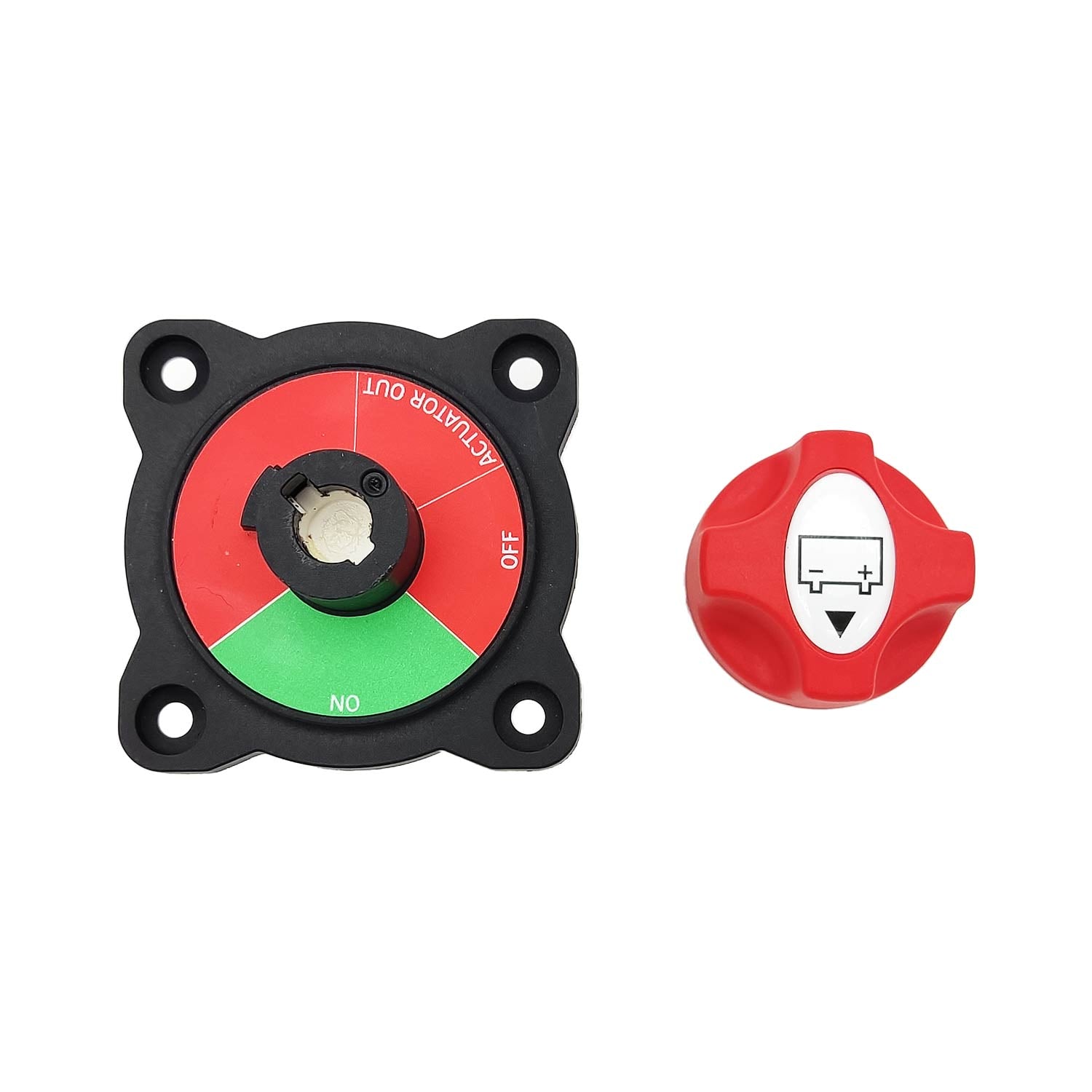

- Switching: On-Off-Control Disabled (On-Off-Actuator Out)

Product Material Information:

- Usage Areas: Trucks and Trucks, Buses, Marine Industry, Commercial Vehicles, Caravans

- Cuts the electrical circuit between the battery and the starter

- Provides effective protection against theft and fire hazard when the vehicle is parked

- All plastic raw materials used have RoHS and Reach Certificate

- It is made of flame retardant material with high thermal resistance.

- Technical drawing dimensions are in millimeters

Product information:

- It is called as universal marine type rotary IP54 protected battery circuit breaker.

- Marine Battery switch has 12V 50V operating voltage values, maximum current capacity is 1000A for 30 seconds

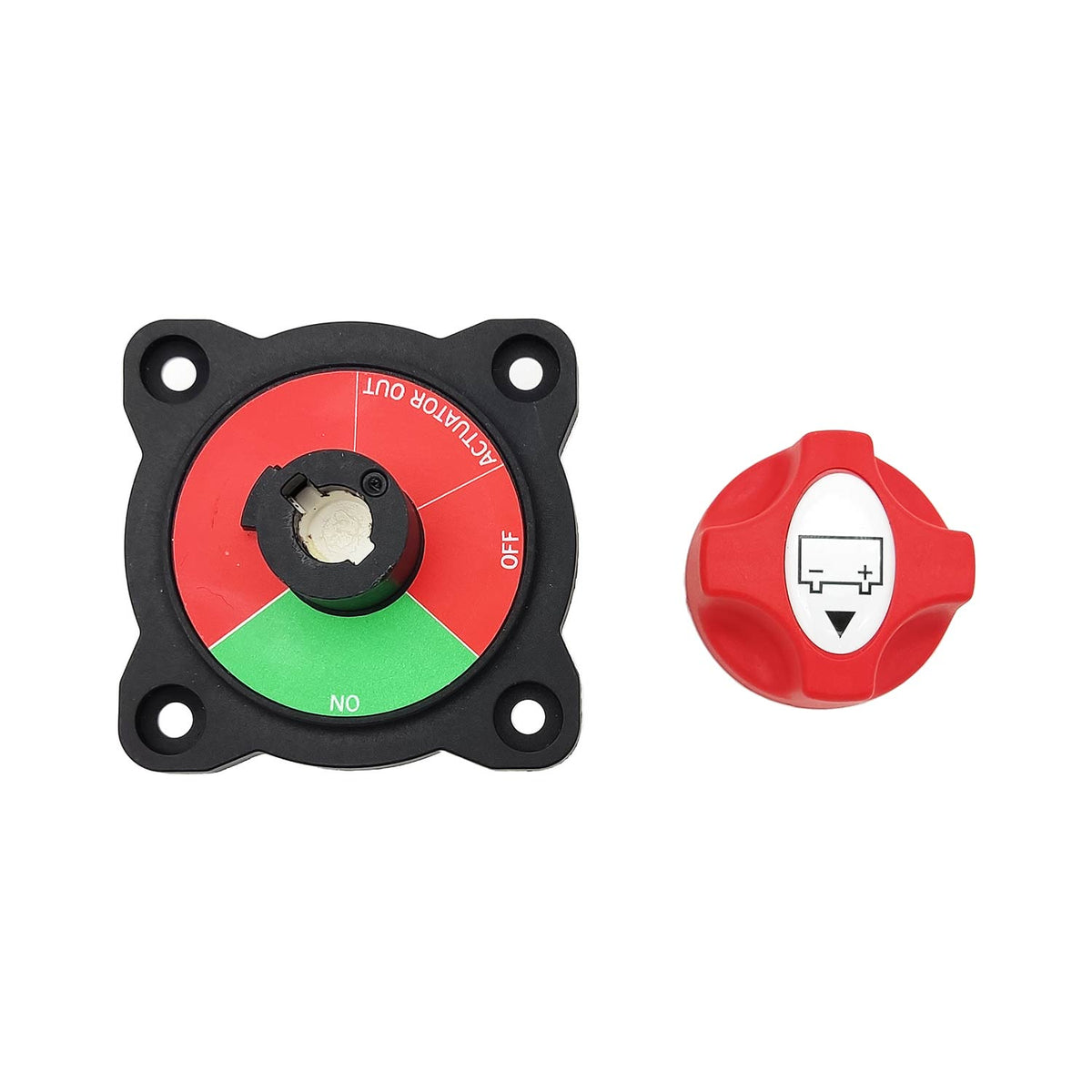

- The rotary marine battery circuit breaker switch product has the feature of removing the key cap.

- Marine boat car truck caravan battery disconnect switch

- Panel circuit breaker switch product On-Off-Actuator Out

- Truck, Caravan battery switch 3 position circuit

Couldn't load pickup availability

Got questions?

Ask a question about the product get in touch